One of my favorite stories to tell is from back in 2009 when we were hosting a photographer from a national publication that was visiting our farm for the first time. She was sent to capture photos for a story about a new product being made on a dairy farm called “CowPots”. We began the tour by walking by the barn where she could see in to where the cows lay down.

*Side Note: any CowPots that don’t meet our quality inspection because they are misshapen or were smushed during production will be recycled as bedding for our cows. We really are a zero-waste stream facility. The photographer noticed the CowPots littered across the bed where the cows rest and she asked, “They come out like that?”

I still get a good laugh from that interaction and as you might have guessed, No, CowPots don’t actually come out like that. There’s quite a bit of processing that happens to turn our cows’ plops into pots. And we’re going to share the critical steps of how we process cow manure here.

The first step is collecting the manure. Our free stall dairy barn was built in 2016 and was designed with alley scrapers placed in the 3 main walkways where the cows roam about. These scrapers continuously run, cleaning the alleyways of manure and urine. It is basically a giant squeegee that is powered by a motor and pulled with a chain.

The cows quickly became acquainted with this slow moving device and just step over it when they’re walking around, from feed bunk to bed to milking robot to rotating back scratcher. The manure is pushed into the center of the barn where it drops into a central pit. (want more deets about our cows and barn life? you can read more on our About Us page along with videos from our farm)

The next step is pumping the manure out of the pit. Farmers wear a lot of hats – agronomists, animal whisperers, equipment operators and also with so many pumps needed on the farm, occasionally they also have to be plumbers! Everyday this truck moves 9,000 gallons of manure out of the barn and delivers it to our anaerobic methane digester.

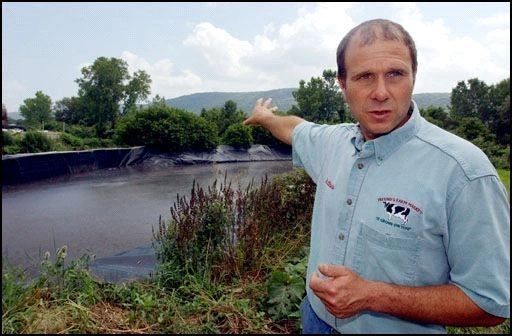

The digester is a U vessel tank, the manure is delivered to one end of the U and we rely on the microorganisms that naturally exist in a cows’ gut to continue doing exactly what they do in the cow. Our job is to keep the temperature in this tank at 100 degrees to mimic the temperature of a cow and the microbes digest the manure and generate methane. The black tarp over the digester allows us to capture that methane and pipe it to a furnace room. On the other end of the U, the manure is pumped (see, another pump) through a separator that squeezes the liquids from the solids. Fun Fact: we have the longest continuously running digester in the USA. This digester was installed in 1997 and we have been collecting the biogas (methane) to burn as a renewable gas to heat our house for 27 years.

The separated liquid portion of the manure is stored in a lined lagoon where we will use a pump (are you keeping count of how many pumps we rely on?) and a dragline system which is a long series of pipes to deliver the fertilizer to our cropland at optimal times, before and after our crop harvests. We may have a dairy farm where the primary focus is cows and milk but we have found important ways to make their byproduct, manure, an asset for our farm. From bedding for the cows to lay on to renewable energy to heat our house and fertilizer to grow our crops each year.

For the purposes of CowPots, we are focused on the separated solids. After separation, the solids are delivered to an invessel composter. This large barrel turns throughout the day and allows the manure to heat as it would in a compost windrow. This heat treatment is an important step as gardeners know you don’t want to apply raw manure to your garden. We mitigate any concerns for weed seeds and nutrient burn with this cow manure compost process. The digested, separated and composted manure fibers spill out and are now ready to be delivered to the CowPots factory.

We form all of our pots, 15 different styles, using a process called Type 2 Pulp Molding. And you better believe this system also relies on a series of pumps (again!) This is the same process used to make egg cartons. The distinction is that instead of using exclusively cardboard or paper, we are using upcycled fibers that are a byproduct from our dairy farm. Our raw material is 100% renewable as the cows provide more of it everyday and it’s recycled because we’re able to first capture energy from that manure before we use it to form CowPots.

After being formed, the pots are dried in large industrial ovens to 0% moisture. Drying our product is essential to eliminate any potential for pathogens that are associated with manure. We run tests with a 3rd party laboratory to confirm that we have eliminated harmful bacteria from the finished product. Dried CowPots are then packed into cardboard cartons and can be stored in a cool, dry place for an indefinite shelf life.

And as mentioned earlier, any pots that don’t meet our quality standards are collected and delivered to the barn biweekly as bedding for the cows. These pots will eventually get scraped back into the barn alleyway when we clean the cows’ stalls and will do a full return to the manure process – digesting, separating, and composting and eventually return to the CowPots facility to be made, yet again, into a CowPot.

We are committed everyday to ensuring that we are manufacturing a sustainable alternative to plastic and peat that leaves our environment and community in a healthier place today and for future generations. From plop to pot.